It’s widely recognized that upgrading the braking system in a track car is one of the premier changes one should consider, before power, suspension, or cosmetics. While the one-stop performance of OEM brakes may lead one to question the necessity of upgrading, it’s important to consider the severity of track conditions versus the street.

It’s widely recognized that upgrading the braking system in a track car is one of the premier changes one should consider, before power, suspension, or cosmetics. While the one-stop performance of OEM brakes may lead one to question the necessity of upgrading, it’s important to consider the severity of track conditions versus the street.

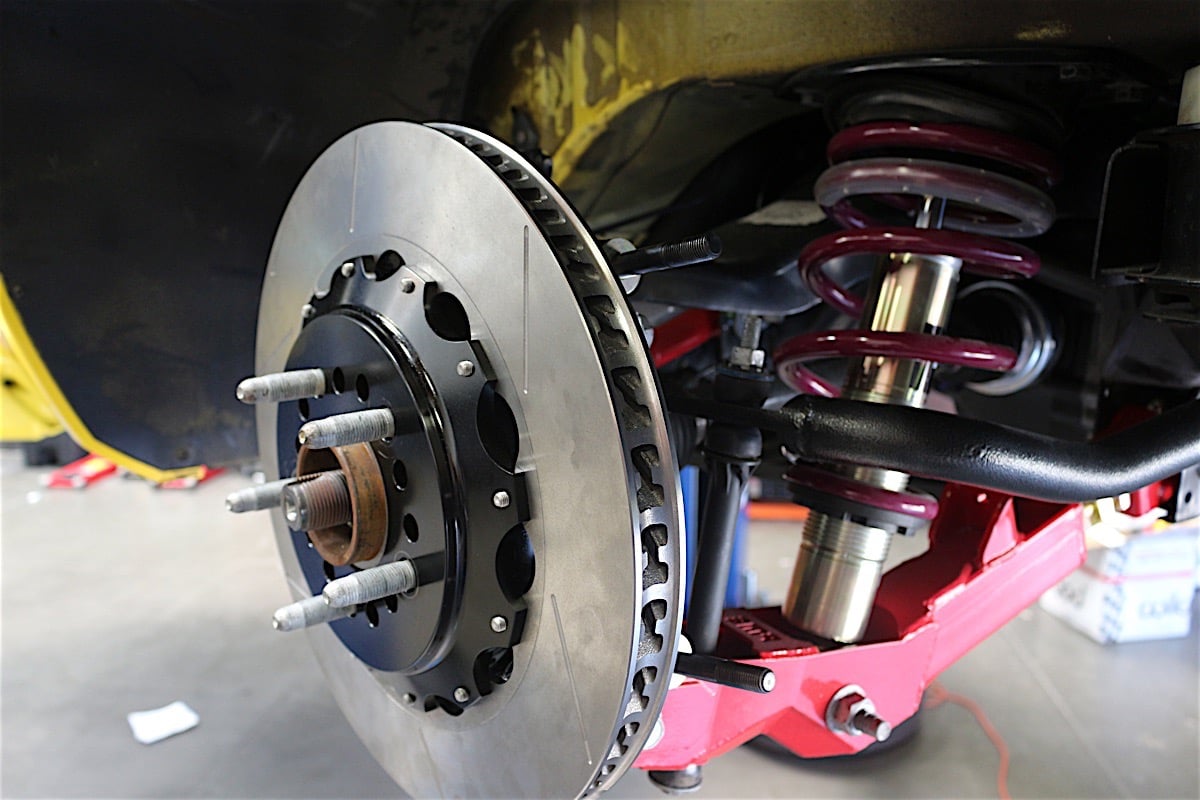

Project Lucky 13 has had a rough life thus far, rolling out of Chevrolet as a shiny new SS Camaro it fell victim to the failing sentimentality of thieves, who ruthlessly plundered it of it’s mechanical valuables. The original brakes remained intact, but we have this car slated for some serious track duty and powertrain upgrades, naturally, brakes needed to follow suit.

When considering how to evaluate a braking upgrade it is important to consider factors beyond pure stopping force and mechanical advantage. A big brake kit offers better clamping leverage due to larger diameter rotors, stiffer calipers, and more aggressive pads but there is more to the system than flashy parts. Performance brakes are all about managing thermal energy. Every time you stomp on the middle pedal you are converting kinetic energy into thermal energy, a given part can only sustain so much thermal energy before it begins to drop in performance — hence brake fade.

When considering how to evaluate a braking upgrade it is important to consider factors beyond pure stopping force and mechanical advantage. A big brake kit offers better clamping leverage due to larger diameter rotors, stiffer calipers, and more aggressive pads but there is more to the system than flashy parts. Performance brakes are all about managing thermal energy. Every time you stomp on the middle pedal you are converting kinetic energy into thermal energy, a given part can only sustain so much thermal energy before it begins to drop in performance — hence brake fade.

A braking system engineered for a specific application like our 2013 Camaro starts us off in the right direction by accounting for master cylinder volume, gross weight, pedal geometry and more. More generic applications may offer performance improvements at the expense of pedal feel, modulation, or longevity. To ensure we got set up with a package that would compliment our end goal of a LS7-powered fifth-gen Camaro tracker we turned to some of the experts at Wilwood.

A braking system engineered for a specific application like our 2013 Camaro starts us off in the right direction by accounting for master cylinder volume, gross weight, pedal geometry and more. More generic applications may offer performance improvements at the expense of pedal feel, modulation, or longevity. To ensure we got set up with a package that would compliment our end goal of a LS7-powered fifth-gen Camaro tracker we turned to some of the experts at Wilwood.

Aerolite By Wilwood

The racing nickel finish not only provides good looks and corrosion resistance, but improved wear for the piston bores.

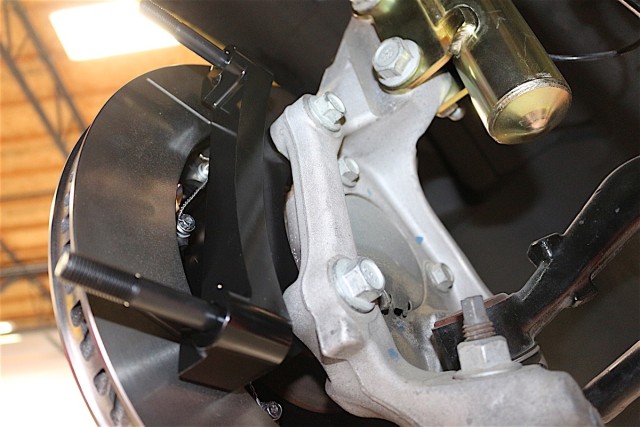

We concluded that to bring our piece of track muscle to a safe stop again and again on the street and the track, we needed to take some cues form the racing world. Wilwood’s Aerolite series of brakes borrows technology and features from their racing line of products and brings those benefits to the savvy consumer who doesn’t need a full-race setup. “The calipers we supplied you guys with are Aerolite series calipers, which originally were a re-design of our W6A which was an open-bridge caliper compared to the Aerolite which is a closed-bridge caliper. Although it’s not a monoblock caliper, it’s a two-piece design with a solid bridge,” explained Michael Scully of Wilwood.

Caliper flex is a concern with less meaty aftermarket units, to address this Wilwood engineered the Aerolite series to include a solid-bride that adds material to the top of the caliper, further developmental improvements include internal cross-over tubes, and convenient pad-swapping access. “Users are reporting less of an issue with flex, meaning more positive feedback form the pedal. Feedback is always a positive thing, the vehicle and brake system is allowing you to understand what the vehicle is trying to do under a hard deceleration,” continued Scully.

Caliper flex is a concern with less meaty aftermarket units, to address this Wilwood engineered the Aerolite series to include a solid-bride that adds material to the top of the caliper, further developmental improvements include internal cross-over tubes, and convenient pad-swapping access. “Users are reporting less of an issue with flex, meaning more positive feedback form the pedal. Feedback is always a positive thing, the vehicle and brake system is allowing you to understand what the vehicle is trying to do under a hard deceleration,” continued Scully.

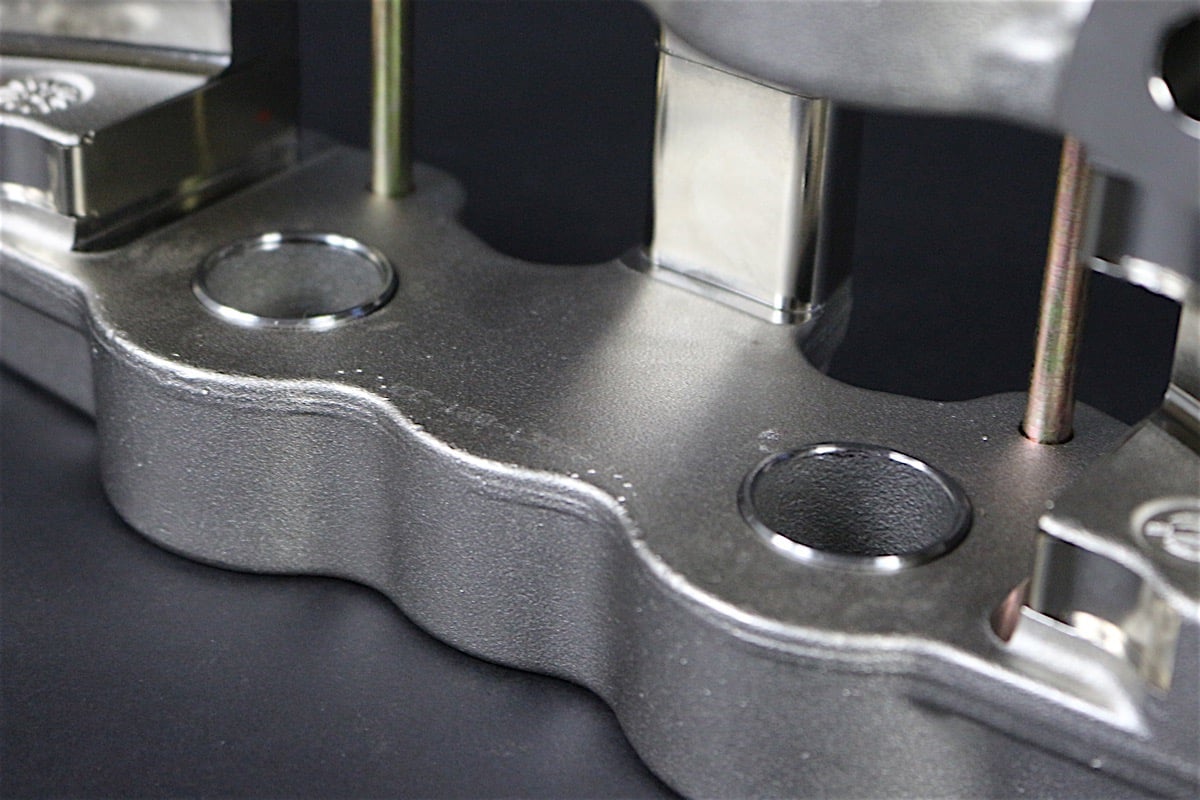

To properly equip the front and rear braking bias of our Camaro we went with 6-piston front (part number 140-11269) and 4-piston rear calipers (part number 140-11270). In the case of the front calipers Wilwood employs a staggered piston design whereby smaller pistons are located on the entry point of the caliper and larger on the exit. This distribution of clamping force is employed for good reason as Scully enlightens, “Essentially staggered piston bore is for pad life, pad wear, longevity and no pad taper, so it doesn’t taper at the front or the back, top or bottom. We also try to match the square piston area very similarly to what came off the vehicle so that as you upgrade the brakes you don’t over-brake and unsettle the chassis because of the car’s ABS, booster or other systems.”

The staggered piston design helps with even clamping forces and pad wear.

It may be easy to grab for the biggest bore piston arrangement money can buy, but the consumer with forethought will know better. If the volume of the brake master cylinder is insufficient to power the high-volume calipers, pedal travel will be excessive and mushy — not the re-assuring feel you expect when barreling into a corner. “We strive to replicate the OEM pedal feel as possible, which is why we do not want to go too much larger. If we go too much larger in the square piston area form a volumetric standpoint of fluid, you’re going to have to stroke the pedal further in order to displace enough fluid,” affirmed Scully.

Moving to the exterior of the calipers we opted to go with a function over form, hard nickel finish. Unlike the polished nickel found on old-school hot rods, of underlying chrome plating, hard nickel is an industrial coating used in many forms of motorsport to offer corrosion resistance and resilience under adverse conditions.

“Nickel has been a newer finish to Wilwood — probably five or six years now. Originally it was designed specifically for racing because of two reasons. Number one; with a powdercoat you are unable to powdercoat the bores for wear resistance but with nickel we don’t mask the bores off, we completely nickel the piston bore and caliper body — second, we have found that it helps with wear on the piston bores. The nickel finish is found mostly in the racing marketplace, however, it is a 100 percent streetable material and finish,” Scully assured.

“Nickel has been a newer finish to Wilwood — probably five or six years now. Originally it was designed specifically for racing because of two reasons. Number one; with a powdercoat you are unable to powdercoat the bores for wear resistance but with nickel we don’t mask the bores off, we completely nickel the piston bore and caliper body — second, we have found that it helps with wear on the piston bores. The nickel finish is found mostly in the racing marketplace, however, it is a 100 percent streetable material and finish,” Scully assured.

Slotted Rotors For Racing Performance

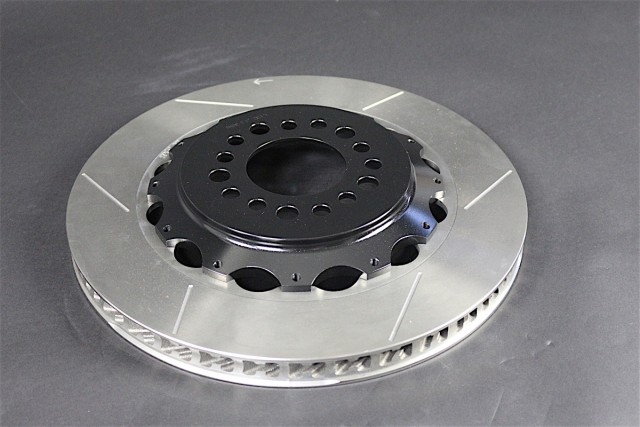

Moving back to the ferrous side of the braking system we find our 14.25-inch diameter slotted 2-piece rotors. Despite being an upgrade in size over the OEM discs, we are actually benefiting from a considerable weight savings. Because the 2-piece design of the Wilwood rotors uses and aluminum center hat we will experience less unsprung-weight at each of the four corners, which translates into less inertia and improved suspension reaction speed.

Moving back to the ferrous side of the braking system we find our 14.25-inch diameter slotted 2-piece rotors. Despite being an upgrade in size over the OEM discs, we are actually benefiting from a considerable weight savings. Because the 2-piece design of the Wilwood rotors uses and aluminum center hat we will experience less unsprung-weight at each of the four corners, which translates into less inertia and improved suspension reaction speed.

Wilwood is known for their proprietary rotor material, Scully filled us in a little on the origination of this Spec-Iron, “Spec-Iron material is proprietary to Wilwood. The material was built around the AM General Hummer, it’s kind of an odd thing for us to go from that field to full road-race type material — we developed that in the harsh environments of hot, cold, sand, snow, water or anything, we built it around that material and transferred it into all of our 13 and 14-inch kits slotted-only rotors.”

Of course rotor design doesn’t stop at the metallurgy of the casting, while drilled rotors are attractive they are more a cosmetic improvement, hardcore racing applications are often slotted-only for crack-resistance and dust or gas dissipation. “When we get into the slotted-only, same as a drilled and slotted rotor, the slots are there to sweep the excess gasses or pad material from between the face of the pad and the rotor. Each time there’s a rotation it’s giving you the best pad to rotor contact, and that’s what works the best in the road race environment. The slotted-only rotors are streetable 100 percent of the time but they do not have the protective coating that the drilled and slotted do, and that is mainly because it’s a racing style rotor,” Scully clarified.

Contributing to the thermal energy-management side of things, heat dissipation is an important side to the upgrade. Stock calipers often route their cooling veins straight out from the center of the hub, simple to make but not the most efficient. “The rotors you have are GT72 design, through the entire swept area there are 72 veins that are curved to pull the air in and expel it out during it’s rotation. We do offer the vein counts in different counts for the small rotors,” he illustrated.

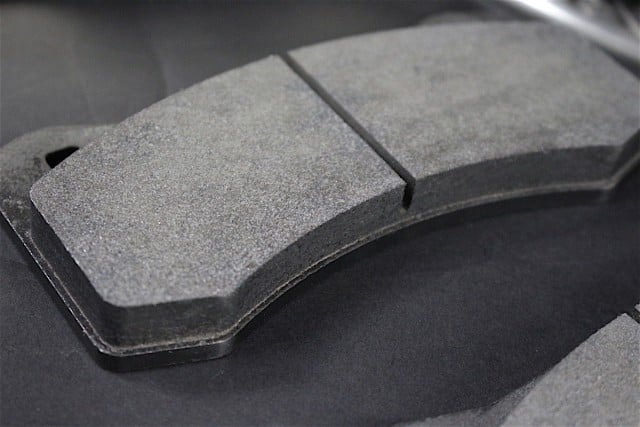

Friction Compounds

Arguably the most important of the three subsystems — brake pads and their friction material need to be carefully considered. While opting for all-out race pads might sound ‘cool’ street performance and drivability will suffer. We opted to field two different compounds; one for the street and one for the track.

“We supplied you guys with two sets of pads, the street pad which is BP10 material, and we upgraded you to a set of BP20 track pads. The BP20 has a lot more coefficient of friction to temperature range over the BP10. The ’20 steps is up so that as the temperature raises the bite actually becomes better, we’ve found that pad works really well for the enthusiast driver who is going to be weekend racing on smaller road courses and autocrosses. We have put them on some larger road courses and had good success, but it’s also depended on the weight of the vehicle,” Scully explained.

“We supplied you guys with two sets of pads, the street pad which is BP10 material, and we upgraded you to a set of BP20 track pads. The BP20 has a lot more coefficient of friction to temperature range over the BP10. The ’20 steps is up so that as the temperature raises the bite actually becomes better, we’ve found that pad works really well for the enthusiast driver who is going to be weekend racing on smaller road courses and autocrosses. We have put them on some larger road courses and had good success, but it’s also depended on the weight of the vehicle,” Scully explained.

Some modern cars have so many safeguards built in to their software that aftermarket modifications can trip safety protocols. The Camaro is not immune to this issue and Willwood is aware of the constraints. To ensure we don’t have problems that force the car into limp-mode they set us up with brake compounds appropriate to the parameters. If we were looking to exceed the expected maximums of the system Wilwood is prepared to tailor a custom package that will work together with the software.

Some modern cars have so many safeguards built in to their software that aftermarket modifications can trip safety protocols. The Camaro is not immune to this issue and Willwood is aware of the constraints. To ensure we don’t have problems that force the car into limp-mode they set us up with brake compounds appropriate to the parameters. If we were looking to exceed the expected maximums of the system Wilwood is prepared to tailor a custom package that will work together with the software.

“My experience with the fifth-gen Camaro chassis is that based off the weight of the vehicle, when you go too aggressive on a pad we’ve seen it trip the computer and throw it into ICE mode. We back a fifth-gen Camaro out of Utah pretty heavily — JDP Motorsports, Jordan himself has been our poster-child for the fifth-gen brake packages. We found that his car went into ICE mode on our most aggressive pad, as we got further in he started manipulating the computer,” recalled Scully. “For the OEM customer, if they’re going to go above and beyond the BP20 material the best thing to do would be to contact Wilwood for help in pad selection. We’ll be happy to take care of those guys so they know what they may be running up against in that situation.”

Installation

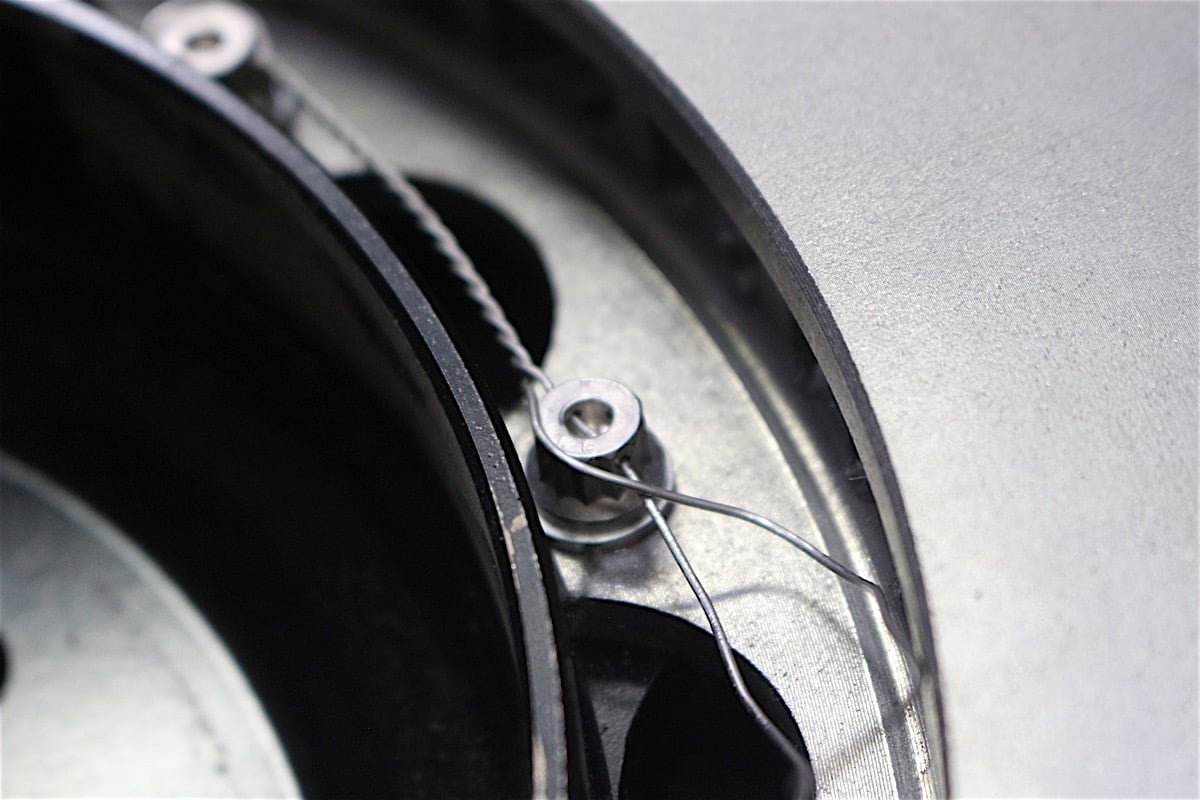

Installing the new big-brakes on the 2013 Camaro was a straight forward process. First came some assembly of the two-piece rotors. Using the supplied hardware we affixed the aluminum hats to the Spec-Iron rotors. For racing security, these 12-point bolts come pre-drilled for safety wire. With our trusty safety wire pliers and some patience we wired-up the torqued hardware, ensuring nothing comes loose on the track.

Safety wiring bolts can be a tedious task but is important.

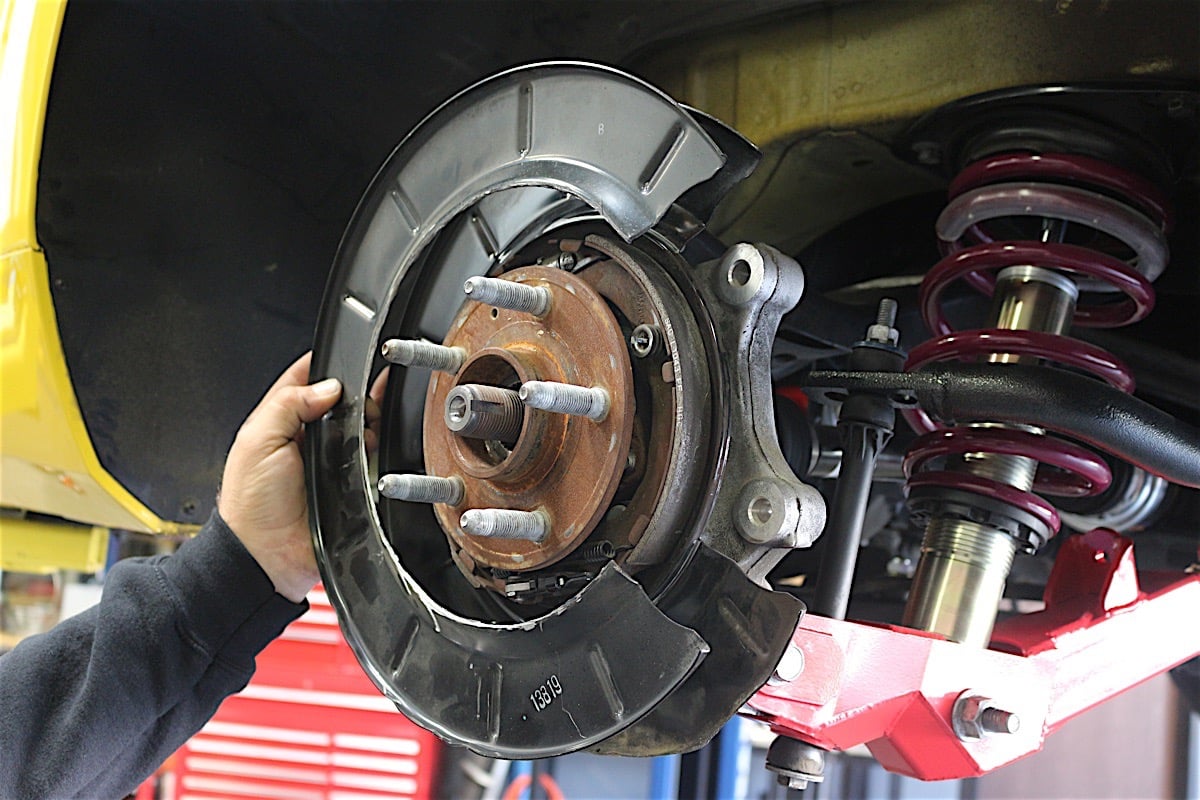

With the completed rotor assembly ready to go on the hub, we slotted the lug-studs through the holes and clamped down the rotor with a couple of lug nuts. With the locating hole lined up we could secure the rotor to the knuckle.

Moving back to the bench we prepared the 6-piston front calipers for installation on the rotors. Small spring clips retain the through-rods that located the pads. With the rods pulled out of the way we installed the pads into the caliper body and retained them with the through-rods and clips.

Installing the pads into the calipers is as simple as removing a few spring clips.

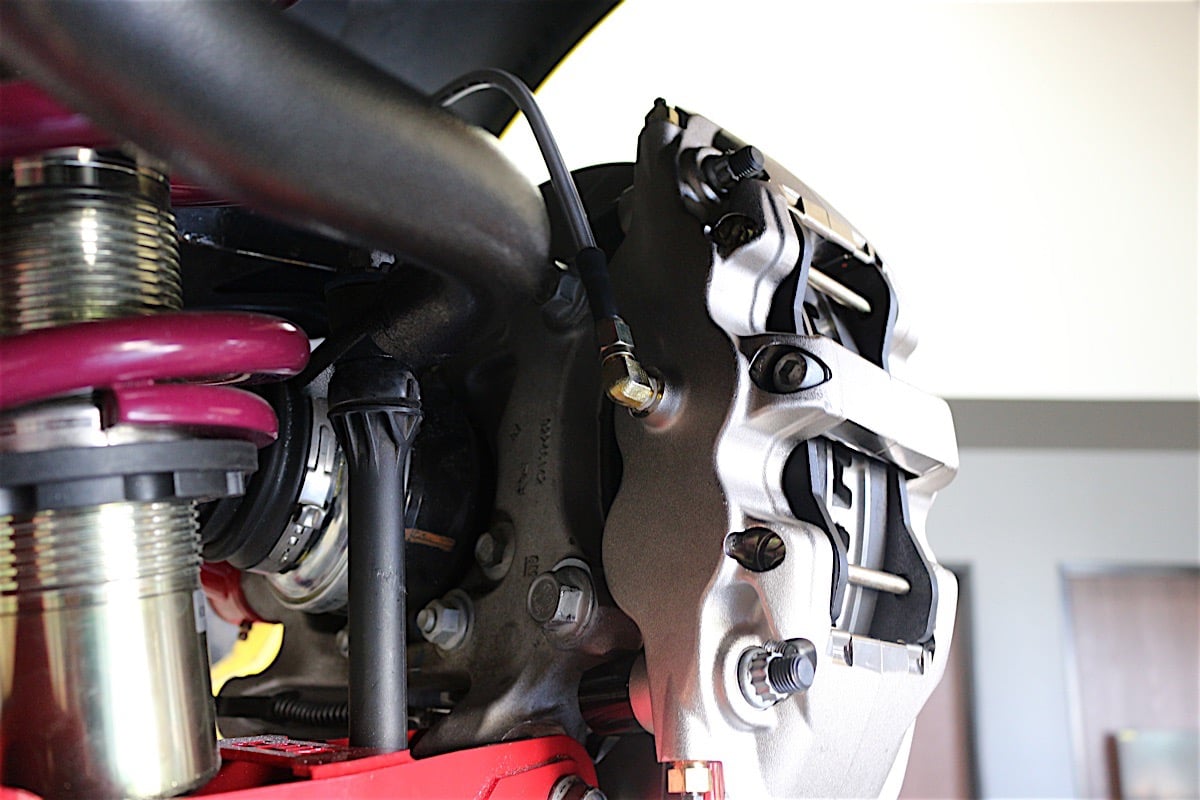

On the backside of the steering knuckle we installed the caliper mounting brackets with the supplied hardware. These aluminum brackets will help locate our new nickel plated Aerolite calipers properly. With the proper torque spec applied we could move on to the pretty stuff — calipers.

The calipers slide easily over the rotors with fully compressed pistons, and pads held apart. We started the mount bolts finger-tight to support the unit, before applying some serious muscle for the final torque.

In the rear of the car, we discovered that the OEM dust covers would need some minor modification for clearance. Our existing shields were a little crumpled as a result of the thieves’ haste so no sentimentality prevented us from taking a cut-off wheel to them. After cutting out the center (which we would retain) we discarded the outer ring.

We cut out the center to keep, and discarded the outer ring of the dust cover.

The rear rotors slip right on the lugs just like the front, the 4-piston calipers require the use of a smaller Wilwood mounting bracket to locate off the stock mounting holes. With everything locked in place we wrapped up this quick installation. Buttoning up the system, we ran the supplied braided flex-lines from the calipers to the body-mounted hardlines. Bleeding the brakes would have to wait as this car is destined for an automatic to manual conversion.

We can’t wait to get it on the ground and put it to the test after some well-deserved break-in procedures. Next up we will get the Camaro into a new set of shoes the fit over our big brakes, billet wheels and sticky rubber will help this fifth-gen on the track. Stay tuned for the next phase of Lucky 13’s build.